Precision Metalwork Without Compromise

EXPERT Tube Bending services in Ashland, IL.

INNOVATors in Tube Bending for 40+ Years

At our facility, tube bending and metal shaping are more than a process; they’re a tradition. With over 40 years of hands-on experience, we produce clean, precise bends and expertly shaped metal to meet your exact specifications. Working with a wide range of materials, shapes, and sizes for industries like automotive and aerospace, we focus on efficiency, minimal waste, and parts that fit right the first time, delivering every project reliably with craftsmanship you can trust.

forging masterpieces out of metal

Decades of expertise combine with advanced technology to deliver exceptional metal fabrication and shaping solutions. Our workshop offers a full spectrum of services, from custom tool design to precision-crafted dies, including tooling specifically for Pullmax machines. Whether you’re a hobbyist or a professional metalworker, we provide the tools, skills, and guidance to help you succeed. Start your metal-shaping journey with us today!

Tube Bending You Can Rely on: expert industrial solutions.

At Fulton Metal Works, we turn your tube-bending challenges into precise, reliable solutions. Using advanced technology and decades of experience, every bend meets the highest standards for consistency and quality. Our services adapt to projects of any size, from custom designs to industrial applications.

What we deliver:

- Accurate bends every time

- Custom solutions for any project

- Durable results built to last

Let us help shape your next project. Contact us today to learn more!

Metal Shaping That Brings Your Vision to Life

Explore the possibilities of metal shaping with our expert craftsmanship. Our skilled artisans combine precision, creativity, and advanced equipment to transform raw metal into functional and visually striking pieces. From simple bends to intricate designs, every project receives meticulous attention to detail. Using tools like the FULMAX Power Hammer, we deliver consistent, high-quality results tailored to the demands of modern applications, ensuring your project not only meets but exceeds expectations.

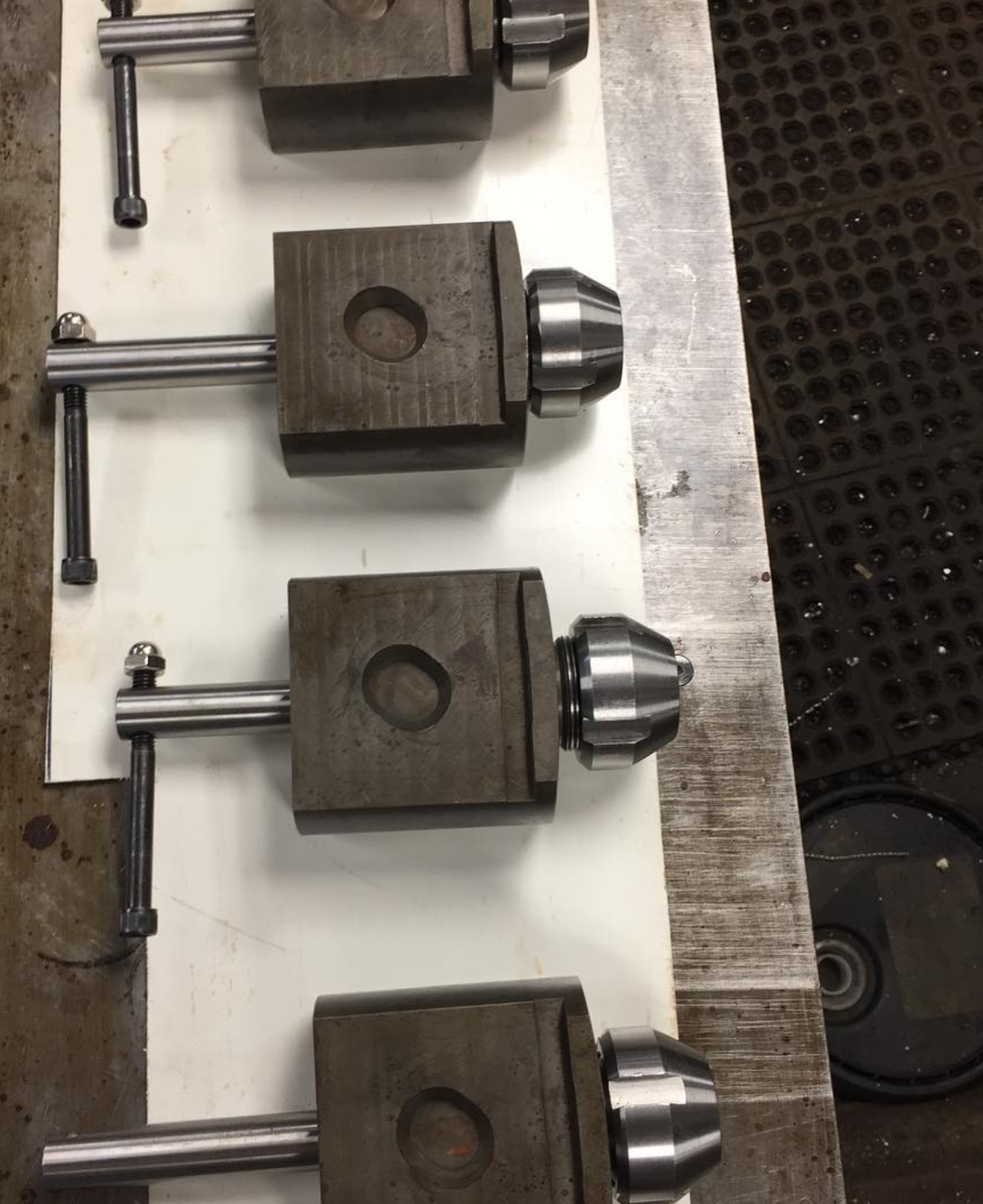

See Pullmax Bead Tooling in Action

See Fulton Metal Works’ precision bead tooling for Pullmax machines in action. These tools deliver unmatched accuracy and consistent results, making professional-quality beads on metal fast and reliable. The demo video highlights their versatility and performance across a variety of metals, showing exactly what they can do.

Product Highlights:

- Fits all Pullmax square shank sizes

- Three bead widths: 1/2", 5/8", 3/4"

- Ability to form defined bead ends

- Fast, reliable, and precise results

With these tools, every bead we create on your Pullmax is clean, precise, and built to last.

Gear Up with tools from Fulton Metal Works

From Pullmax dies to power hammer tooling, every tool is built for precision, durability, and performance. Whether you’re a hobbyist or a professional, our store has the equipment you need to bring your projects to life. Click below to explore our full range of expertly crafted tools and see how they can elevate your metalworking projects.

cutting-edge Commercial-Grade Metal Shaping with the FULMAX power hammer

The FULMAX Power Hammer is a modern, commercial-grade machine designed for serious metal shaping. The FULMAX Model LR-30 has been extensively tested over three years to ensure reliability and performance. Designed with input from top metal-shaping professionals, it addresses long-standing design limitations while providing unmatched precision and control.

Key Features:

- Quick-change dies for faster workflow

- Rounded dies for cost-effective manufacturing

- Variable Frequency Drive (VFD) speed control

- Rotating mass aligned with the support beam to eliminate side shake

- Steel-reinforced concrete main column for stability

- Fully adjustable stroke and shut height

- Commercial-grade quality at a reasonable price

The FULMAX Power Hammer is built to deliver consistent, high-quality results. Reach out today to learn more!

Hear From Fellow Metalworkers

Don’t just take our word for it; see what metalworkers and hobbyists alike are saying about Fulton Metal Works. Our customers trust us for precision, durability, and results that exceed expectations.

Frequently Asked Questions

If you don't see the answer you need, feel free to reach out to us for assistance.

Why is Fulton Metal Works so popular?

Fulton Metal Works stands out as a premier destination for tube bending in Ashland. Our expertise in tube bending sets us apart thanks to our dedication to innovation, precision, and quality. It is our tube bending services that keep our clients coming back. Our team is skilled in using cutting-edge tools and techniques, enabling us to handle complex tube bending projects with ease. This commitment to excellence has made us a leader in the industry. Discover why so many in the region trust us for their tube bending needs, and experience the difference that dedicated tube bending services make in your projects.

Where can I find expert tube bending services in Ashland?

Look no further than Fulton Metal Works for expert tube bending services in Ashland. Our skilled team uses state-of-the-art equipment to deliver precise and reliable results every time. Whether you need custom tube bending for industrial or artistic projects, we have you covered.

What materials can be used with thumbnail shrinking dies?

Our thumbnail shrinking dies at Fulton Metal Works are designed for versatility. They work effectively with various metals, including softer metals, thanks to our non-marking plastic tops. For steel projects, our interchangeable steel tops can handle materials up to 16 gauge.

What is the purpose of doming dies in metal shaping?

Doming dies are essential for stretching soft metals into desired shapes. At Fulton Metal Works, our plastic doming dies are compatible with Pullmax-style machines and designed with replaceable plastic tops. They allow for precise shaping of metal, enabling artists and professionals to achieve unique metal formations.

How does the FULMAX Power Hammer improve metal shaping?

The FULMAX Power Hammer revolutionizes metal shaping with advanced features like quick-change dies, variable speed control, and enhanced stability. Developed with input from leading professionals, it minimizes side shake and maximizes control.

Can Pullmax machines be used with beading and louver dies?

Absolutely! Our beading and louver dies are specifically designed for use with Pullmax-style machines. They offer various bead and louver sizes to cater to diverse project needs. Improve your Pullmax operations with our efficient beading and louver dies available in multiple shank sizes.

Talk Metal With Us

Fill out the contact form below, and a member of our team will reach out as soon as possible.